Automotive

The mobility market is characterized by dynamic changes. These are centrally linked to the advancing connectivity of vehicles, the progress in driver assistance systems and research into autonomous driving, as well as the rise of infotainment systems. All these factors are driving the rapidly growing use of electronic components. This puts an increasing relevance to a number of challenges for manufacturers and other players in the market: 100% reliability of components with maximum performance and at the same time efficient and cost-optimized production.

Sophisticated production processes for quality & efficiency

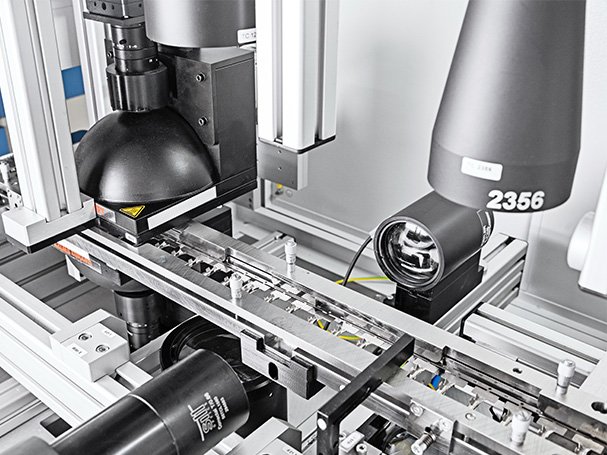

The robustness and durability of components play a key role in the mobility sector. Whether high temperatures and vibrations in conventional combustion engines or high currents in electric drives – components are exposed to constant stress. The miniaturization of electronic components is also leading to ever tighter tolerances. We meet the requirements for the highest quality right from the start of a project by means of end-to-end system-supported quality management, proactive optimization and production-oriented product design as well as the intelligent design of our production lines. Thanks to our sophisticated and coordinated processes, we are able to produce outstanding products for our customers in a cost-efficient and customized manner.

Extensive manufacturing depth for individual requirements

For the production of fully customized solutions, we combine all the necessary expertise under one roof. From the production-oriented design of products and processes to the manufacture of all operating materials and their assembly to high-performance progressive tools and injection molds, we can check all relevant components before the start of series production and design them for the highest quality. Our state-of-the-art machinery with the most precise testing and measuring technology enables maximum efficiency with consistently high precision in fully and semi-automated production lines. Further processing in our finishing processes extends our depth of added value to include cleaning processes, packaging processes and product-specific special requirements.

Variant production for flexibility & synergies

The mobility sector is increasingly characterized by cost pressure and the need to rely on standardization and platform technologies in order to realize synergy effects. With our highly qualified team in design & development, tool making and mold making, we design tailor-made high-performance tools and production processes that make variant production easy. Whether varying material combinations, modified geometries or additional assembly steps – we integrate the entire spectrum of our technologies in an ideally coordinated manner.

Broad portfolio for a variety of functions

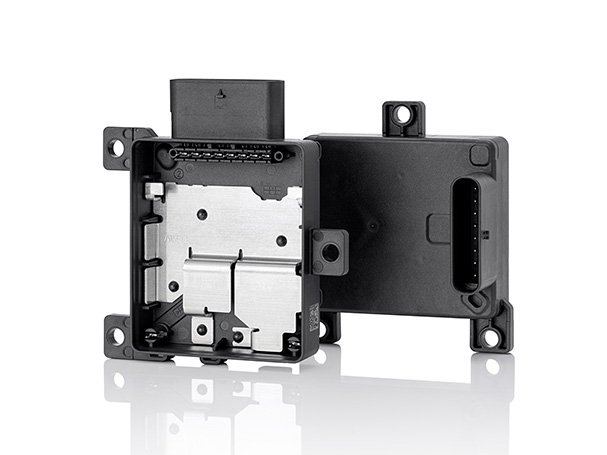

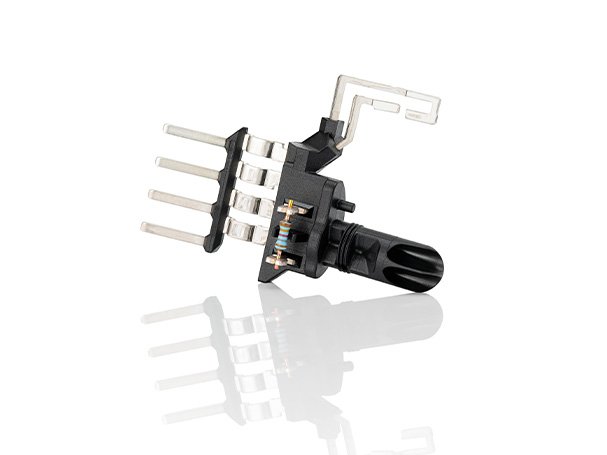

Our range of products is geared towards the needs of the mobility sector, leading trends and state-of-the-art technologies. From wiring system connectors in HV and HF applications to housings and components for sensor technology, battery management systems and charging infrastructure through to traditional springs and components for fuel injection, we produce stamped parts and parts in plastic-metal composites in certified quality (IATF 16949) at all our locations.

Solutions for a dynamic future.

Mobility Solutions Flyer

Find out about the special features and benefits of our technologies and our portfolio in the mobility sector.ortfolio im Bereich Mobility.

Get in touch

Our team of mobility experts will be happy to help you with your concerns, technical questions and project ideas.

Phone |

|

| +49 7321 15410-0 | sales@de.kramski.com |

Telefon

Industries & Applications

Each industry has its own dynamics – its own standards, challenges, and future questions. As a globally operating development partner, KRAMSKI is at home in a wide variety of industries – from medical technology to the semiconductor industry, from mechanical engineering to mobility.