Prototyping

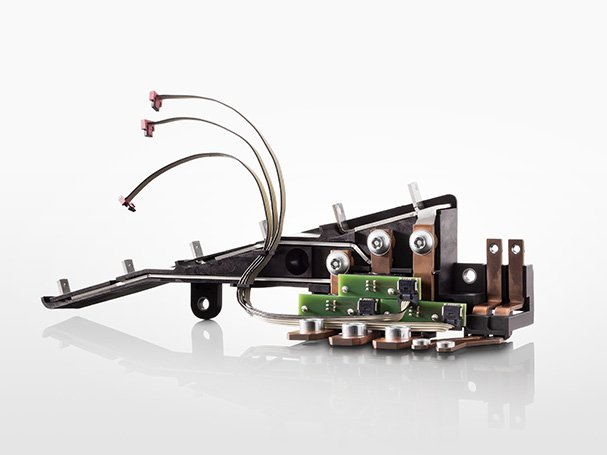

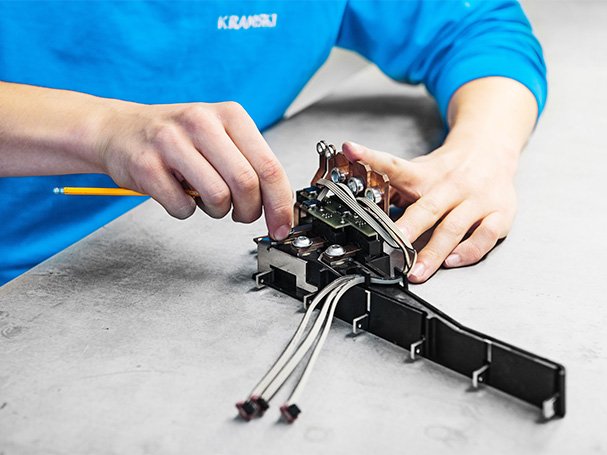

Our prototype construction service aims to trial a new design or process in a version that is as close as possible to how it would be produced in series. In close coordination with our customers, we create sample concepts for all kinds of parts and perfectly tailor these to their requirements.

Ensurance of serial production

and proof of feasibility by means of trialling function-relevant parts well in advance of series production

Fast response time & series maturity

by means of a targeted series of tests in short implementation cycles that specifically verify the feasibility

Diverse technologies & modern machinery

combined with decades of experience guarantee an autonomously operating prototype construction service with the quickest of response times

Flexibility on all levels

through the involvement of partners to represent the desired level of vertical integration

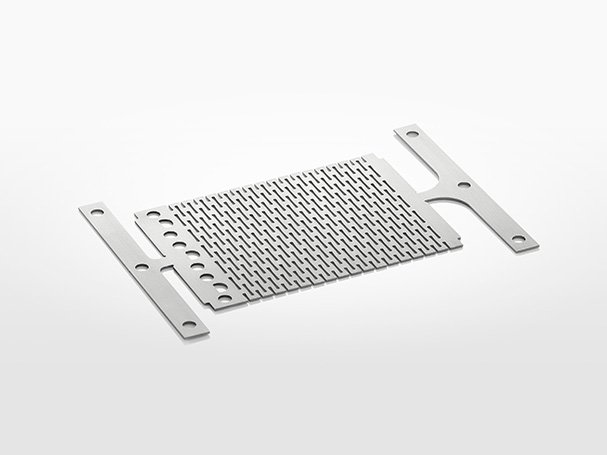

Laser-cut parts

Since time and costs constitute the main bottlenecks during the prototype phase in particular, we offer laser-cut parts. We are able to manufacture these in a timely manner and at an attractive cost. Through this service, parts can be partially or fully cut from sheet metal and then stamped, embossed, or bent in subsequent work steps.

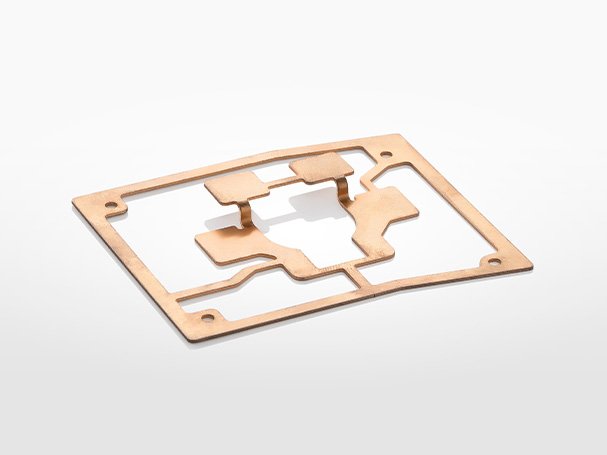

Stamped, bent & embossed parts

On stamped parts, we can use sample tools to carry out stamping, bending, or even embossing operations. Furthermore, upon customer request, we also offer sample tools that are designed with sufficiently high quality to allow initial small batches to be produced with them. The precision of our tools at this stage closely approximates the requirements for series production.

Injection-molded prototypes

In order to manufacture overmolded prototypes quickly and cost-effectively, we implement these in our master molds using insert technology. Using this manufacturing method, process experience of the prototype can be gathered and evaluated directly. We can even produce initial small batches in a manner approximating series production with this tool quality.

Stamping technology

Our core areas of expertise include the series manufacturing of highly precise stamped parts with the integration of various methods into the stamping process.

Injection-molding technology

Another of our core areas of expertise lies in combining stamped metal insert parts and plastic in semi- and fully automated series production.