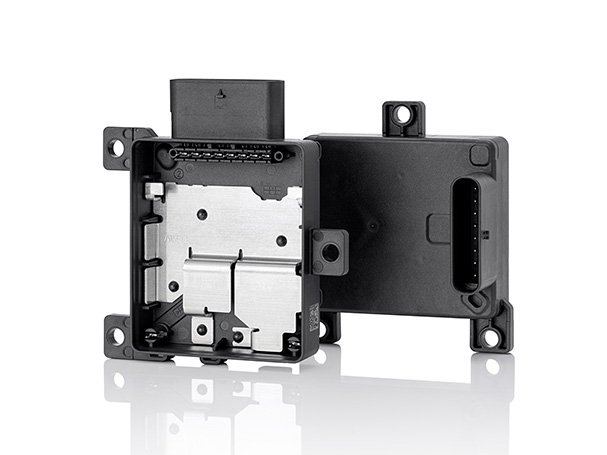

Assemblies

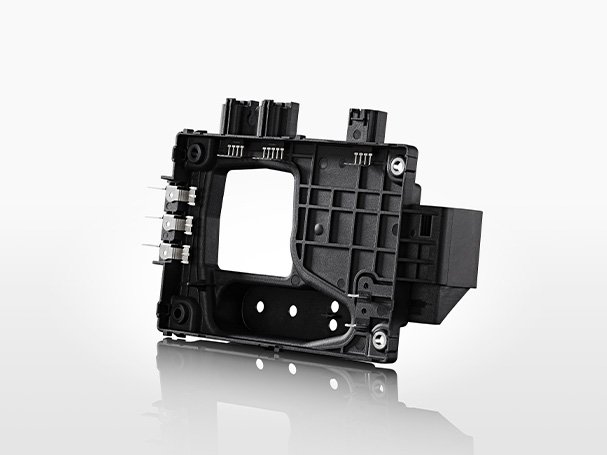

Thanks to innovative product design and synergies in the production process, we have virtually limitless options when it comes to customer-oriented manufacturing of system assemblies. From mounting assembled printed circuit boards (PCBs) with solderless press-fit solutions and mounting seals and housing applications to assembling electronic components.

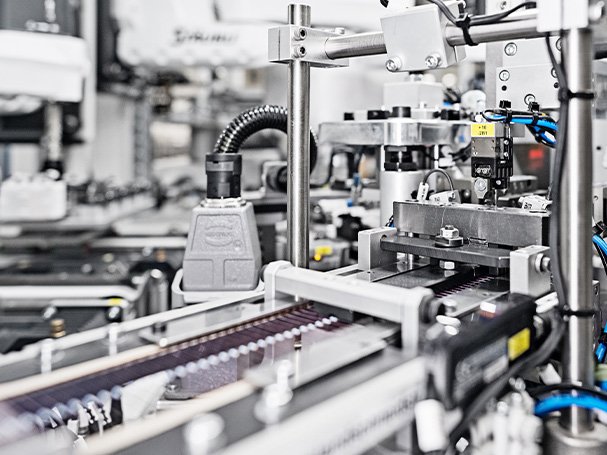

Fully automated

assembly mounting

Maximum automation of complex products (such as sensor housings for medical technology and the automotive industry) means that product costs can be kept in line with those of the market while maintaining top quality requirements. Thanks to our multi-award-winning product systems with integrated quality checks (in-line camera check), we enable a 100% check to be carried out, thus ensuring premium part quality with maximum efficiency.

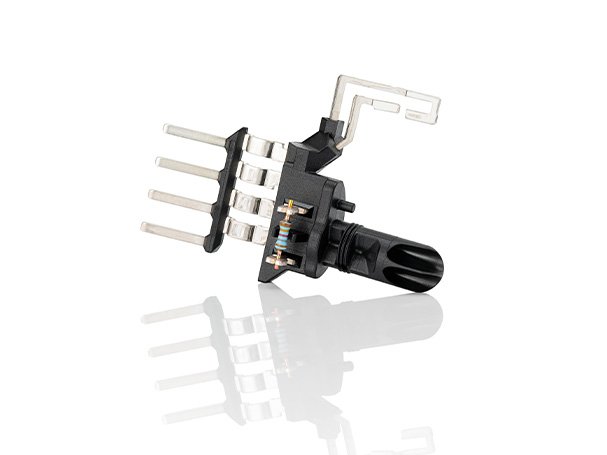

Strip-molded assemblies

(Reel-to-reel)

We provide our customers with support when designing stamped parts as early as the product development phase to achieve strip molding in series production. Using the reel-to-reel method, we achieve a high level of productivity while maintaining a low level of investment costs in relation to output. Environmental requirements and efficiency aspects are the driving force that push us to design sprue systems with direct gating that conserve resources as much as possible. Additional processes can be integrated into the production line, for example:

- Resistance welding processes for integrating electronic components

- Servo presses with bending tools

- Camera testing systems for 100% monitoring

- Laser marking with data matrix code